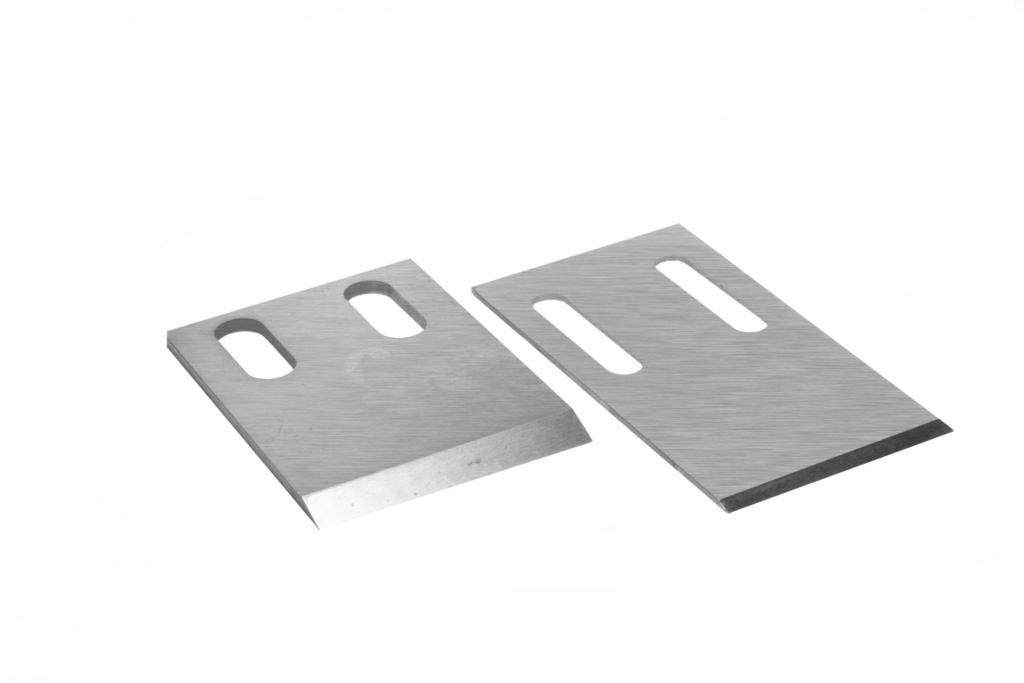

We stock pelletizer knives for all common machines. Through special heat treatment processes, our pelletizer knives function very well with your die face. Our pelletizer knives will last as long as original knives and not damage your die plate. Styles available include:

- Straight

- Fan

- Double sided

Steel grades available depending our your pelletizer and input material:

- Springsteel

- 1.2379 (D2) 12% chrome steel

- 1.3343 (M2) high speed steel HSS

- ASP23 (PM) powder metallurgic steel

Our laserfilter disks offer high performance at very competitive cost.

After years of R&D and investment in top quality manufacturing processes we are able to supply replacement laserfilter disks. Lab tests show that these filters have the correct size, shape and open area of holes. High quality steel grades and surface treatments ensure extreme wear resistance. Our laserfilter disks can process large volume throughputs at high pressure.

Available hole sizes range from 90 micron up to 800 micron. Suitable for filtering of PP / LDPE / LLDPE / HDPE / PS / EPS / XPS / ABS / PVB on all well-known melt filter systems for recycling, compounding and converting lines.

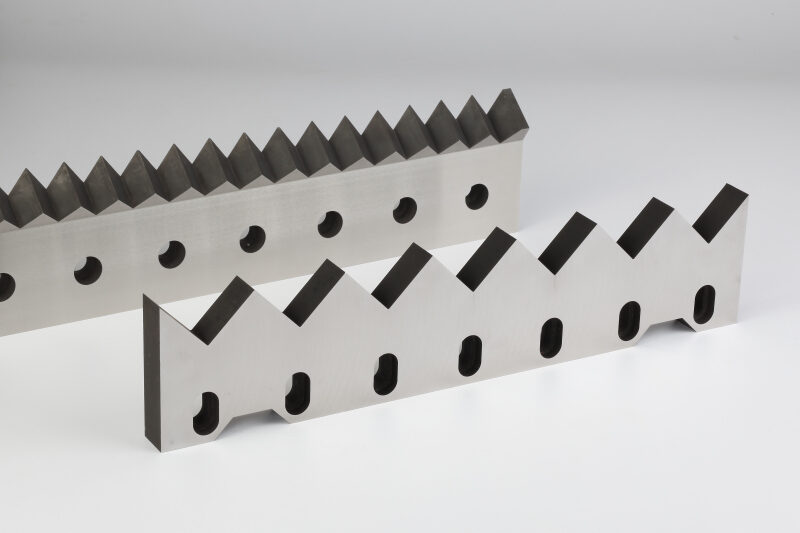

Together with shredder blocks, the stator knives are the central cutting tools in a shredder. We supply stator knives for single shaft shredders. Our knives are produced according to OEM specifications to ensure the correct fit to your machine. We stock most common sizes for popular machines.

Combination of high quality raw materials, CNC controlled machinery and vacuum heat treatment at competitive prices make our knives value for money. Different styles available include:

- Single sided

- Double sided

- Flat profile

- Angled profile

- Countersunk, threaded or slotted holes

Depending on the application, different grades of steel and heat treaments give the best performance:

- 1.7131 case hardened for contaminated input materials

- 1.2379 through hardened for most standard input materials

- 1.2343 through hardened for abrasive input materials

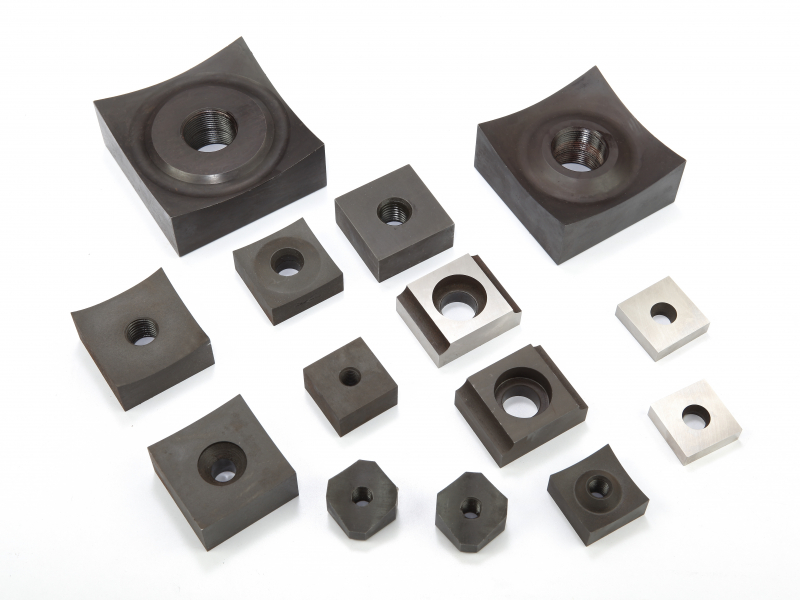

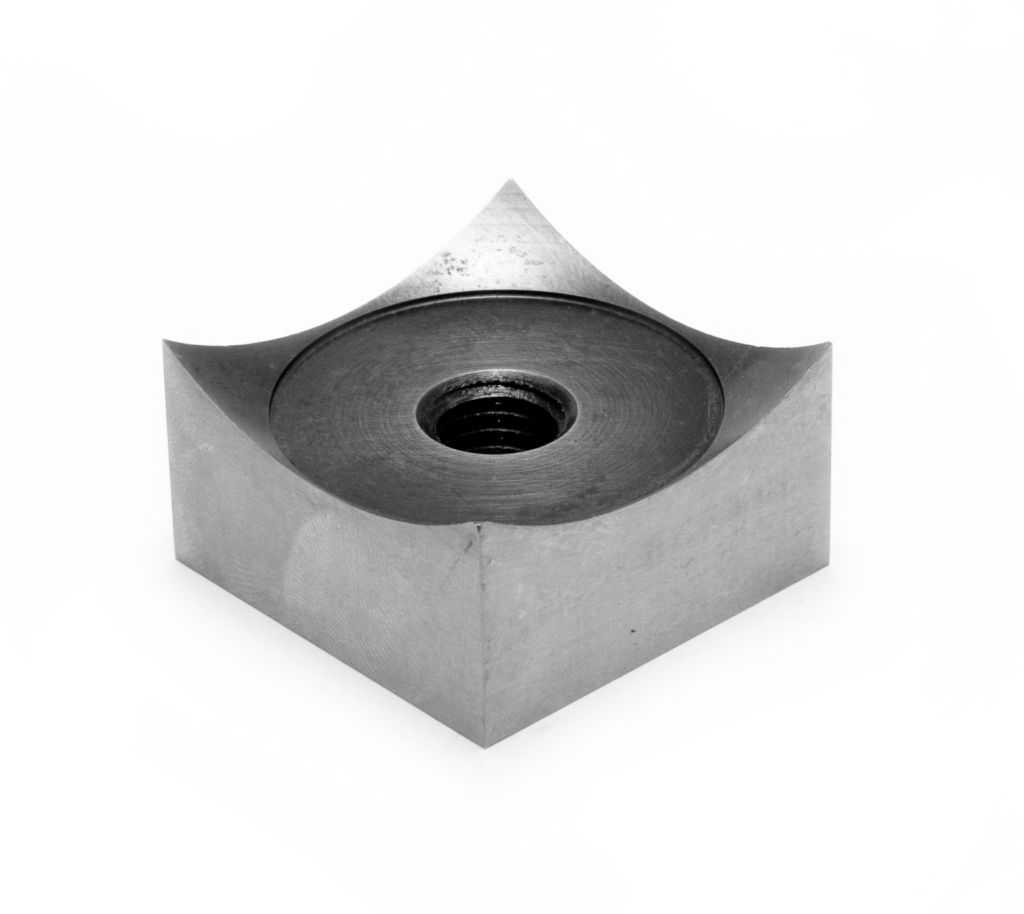

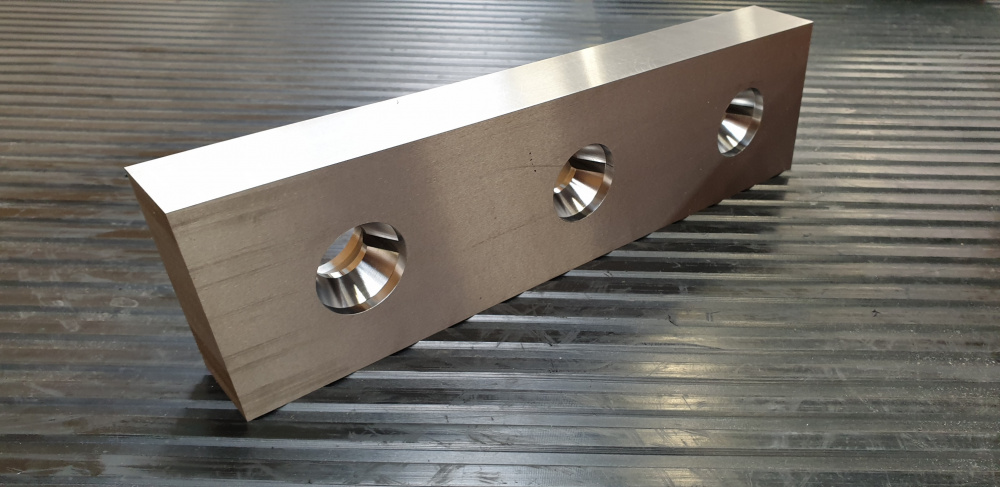

We supply shredder blocks for all single shaft shredders. We stock a broad range of blocks for populair equipment, available for next day delivery. Different shapes and styles available including:

- square, octagon , round and diamond shapes

- concave (radius), flat and hooked profiles

- with threaded, conical, countersunk and straight holes

Our shredder blocks are produced from high quality raw materials and heat treated in vacuum furnaces for optimal wear and impact resistance. Depending your input material and process, we can recommend the most suitable steel grade and hardening:

- 1.7131 case hardened for input materials with high level of contamination.

- 1.2379 through hardened for general purposes.

- Tungsten carbide inlay and solid for exceptional lifetime when processing abrasive input materials.

Besides many standard items, we also produce shredder blocks according to a drawing or sample

We offer a wide range of granulator knives for immediate delivery from The Netherlands, including:

- Rotor knives

- Stator knives

- Deflector knives

Our granulator blades are produced from premium materials using advanced CNC equipment, and each blade is heat-treated in state-of-the-art furnaces. These blades undergo triple tempering to achieve the optimal microstructure for maximum performance.

Key Features of Our Granulator Blades:

- Excellent wear resistance, toughness, and strength for extended durability.

- Manufactured to meet or exceed OEM specifications.

- Reverse engineering available to improve blade performance and longevity.

We stock knives for all major granulators and offer a variety of steel grades to meet different processing needs:

- 1.2379 (D2) – Standard quality, ideal for all material streams.

- HSS Inlay (M2) – Enhanced lifespan for processing abrasive plastics.

- ASP Inlay (PM) – Ideal for processing rubber, EPDM, and soft materials, offering improved longevity.

- TC Inlay (TC) – Best for clean material streams, processing abrasive materials like steel cord and fiberglass. Up to 10x longer lifespan between sharpenings compared to 1.2379 (D2).

We produce knives according to OEM specifications.

Our technical department can reverse engineer and improve your blades for improved performance.

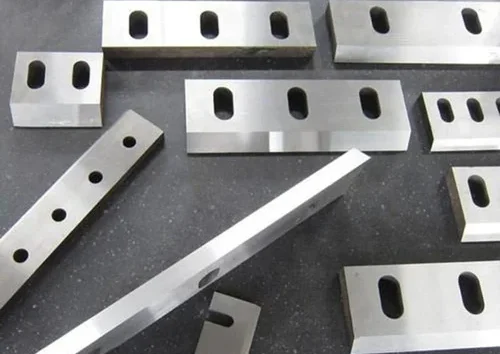

Our scrap shear blades have exceptional durability and are suitable for use on high capacity hydraulic processing shears in excess of 2,000 tonnes. With vacuum heat treatment and triple tempering, our scrap shear blades achieve high strength, toughness, wear resistance and stability at working temperatures. Materials provided include:

- 1.2746 (Nickel alloy)

- 1.2767

- 1.2379